Long live secondary fibres: the virtuous circle of packaging

According to the data in the Recycling in Italy 2022 report, developed by the Sustainable Development Foundation, the Italian recycling industry generates an added value of €10.5 billion (increased by 31% from 2010 to 2020) and produces large quantities of recycled materials, including over 5.2 million tonnes of paper and cardboard.

Among the recycling chains, the paper one stands out: in 2021, 63% of paper and cardboard produced in Italy was made from recycled fibres.

The opportunity in paper recycling

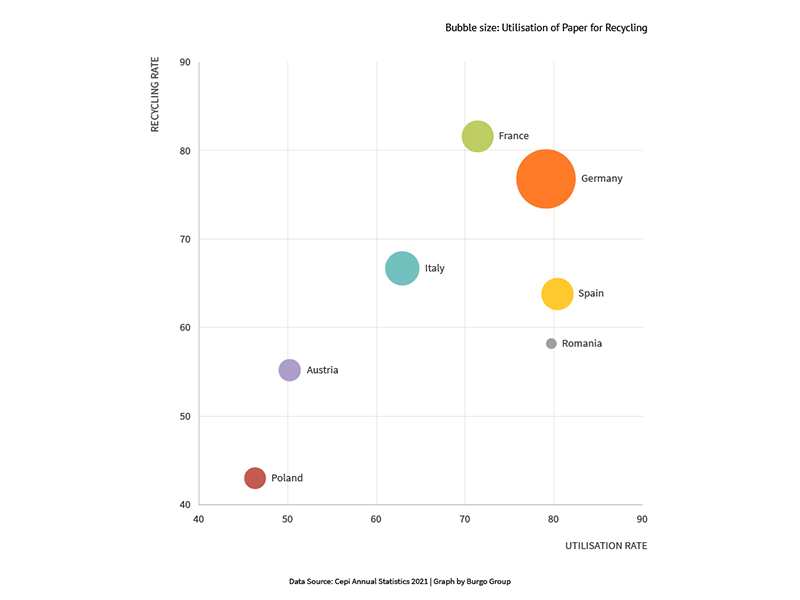

The data on the collection and use of paper for recovery (PfR) in Italy is encouraging; however, it shows room for improvement, especially when compared with other European countries.

The size of the "bubbles" in the graph represents the amount of paper recovered in individual countries. Italy is the second largest recycler in the EU, right after Germany, while other countries are still ahead in the collection.

The analysis highlights an interesting opportunity: the collection of paper for recovery would already allow for greater reuse than is currently practised. Furthermore, the recovery and utilisation trends are both increasing, also thanks to investments in the sector that have stimulated the utilisation rate.

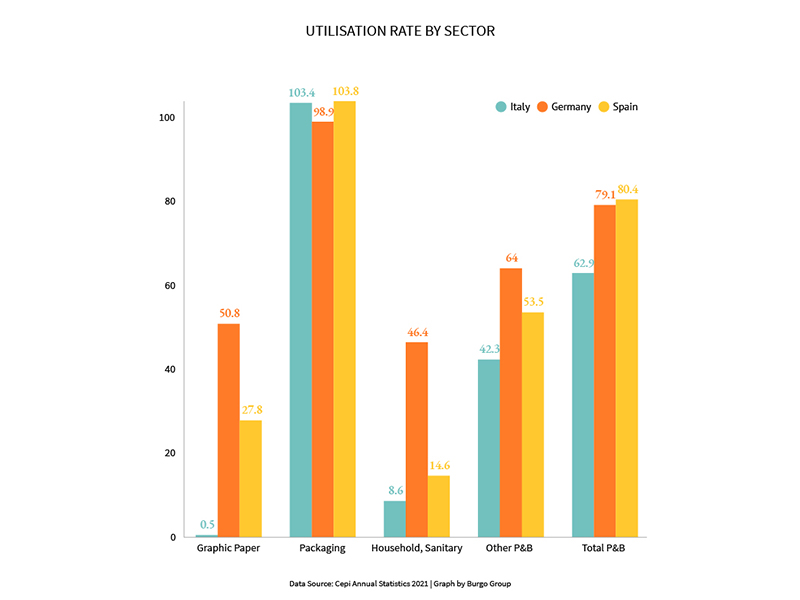

The record in the packaging sector

Depending on the reference sector, the recovery rate and the use of recycled paper show marked differences. In the packaging sector, Italy records a truly enviable rate of use of recycled paper.

The recycling rate of paper packaging in 2021 reached 85%, exceeding the European target set for 2030. In essence, Italy produces packaging almost exclusively with recycled paper.

Burgo Containerboard: a circular packaging

Recycling embodies an extraordinary development opportunity for the paper industry, seized by Burgo Group with the investment that led to the conversion of the Avezzano plant for the production of the Burgo Containerboard range.

The paper mill provides an annual production of 220,000 tons of paper 100% made with secondary fibres, i.e. waste paper from sorted collection, packaging recovery, and processing scraps, which enables a significant reduction in the consumption of resources, production waste, and CO2 emissions.

The range includes topliner, testliner and fluting papers, all available with FSC® and PEFC certification.

Discover Burgo Containerboard products: updated features, accreditations and data sheet.

Find out moreBurgo Containerboard papers are utilised for corrugated cardboard packaging solutions that are perfect for a variety of needs and applications, including those requiring high performance.

BCB Frost, for instance, is a strong fluting paper developed to create durable packaging that ensures excellent performance in humid environments.

BCB Dual, on the other hand, is a remarkably versatile double-use paper that can be utilised both as a fluting and as a liner, thus allowing to reduce the types of paper in the warehouse and their relative costs.

An undeniable advantage of containerboard packaging solutions is that once their function is completed and they are sent for recycling, they can become raw material. The fibres, consequently, re-enter the production process and become new packaging, in a virtuous cycle.